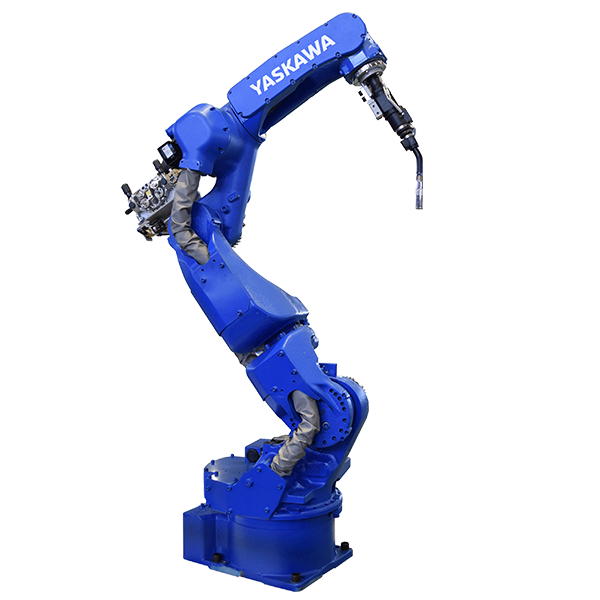

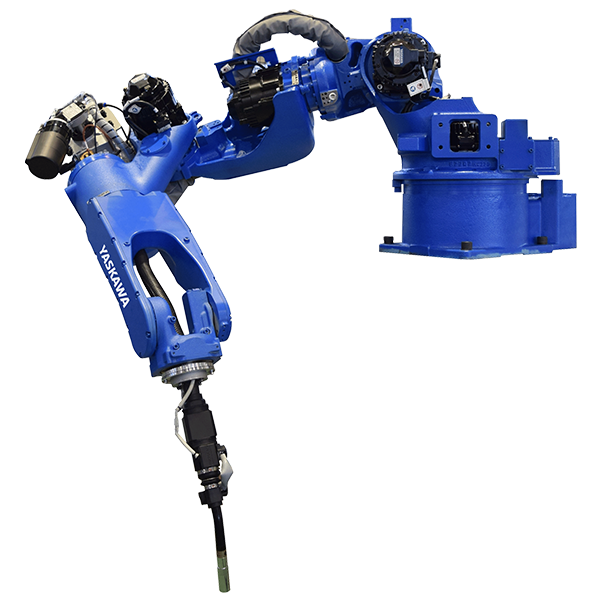

Robot Optimized for Arc Welding - Robot with smart arm design to reduce interference with peripheral facility

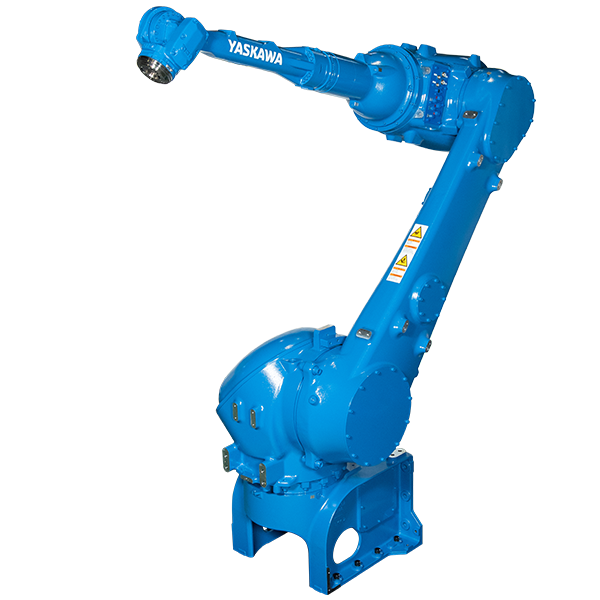

MOTOMAN-AR Series

AR1440

AR2010

AR1440E

WELDING POWER SOURCE

Digital inverter based welding power source developed specifically for

MOTOMAN robots deliver quality welding.

MOTOWELD-X350, X500

Welding Method

CO2 short-circuit welding, MAG short-circuit welding, MIG short-circuit welding, Pulse MIG welding, Pulse MAG welding

Welding Material

Iron, Stainless Steel, Aluminium

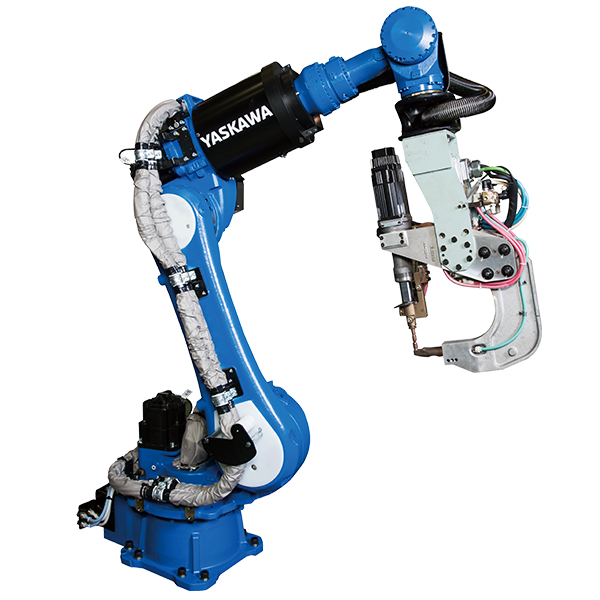

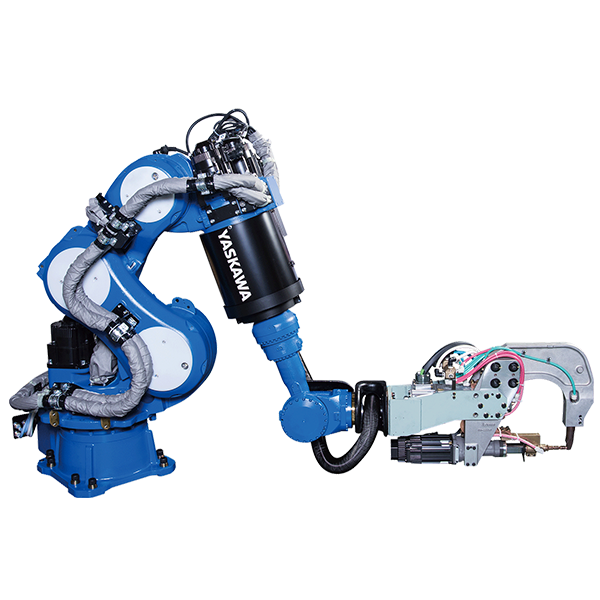

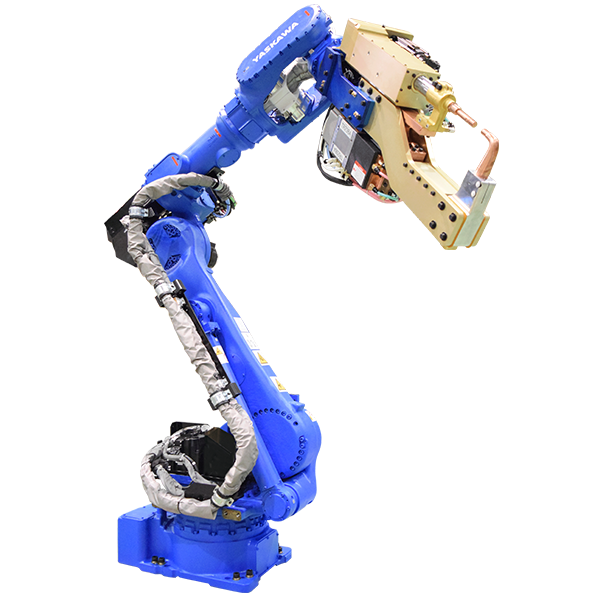

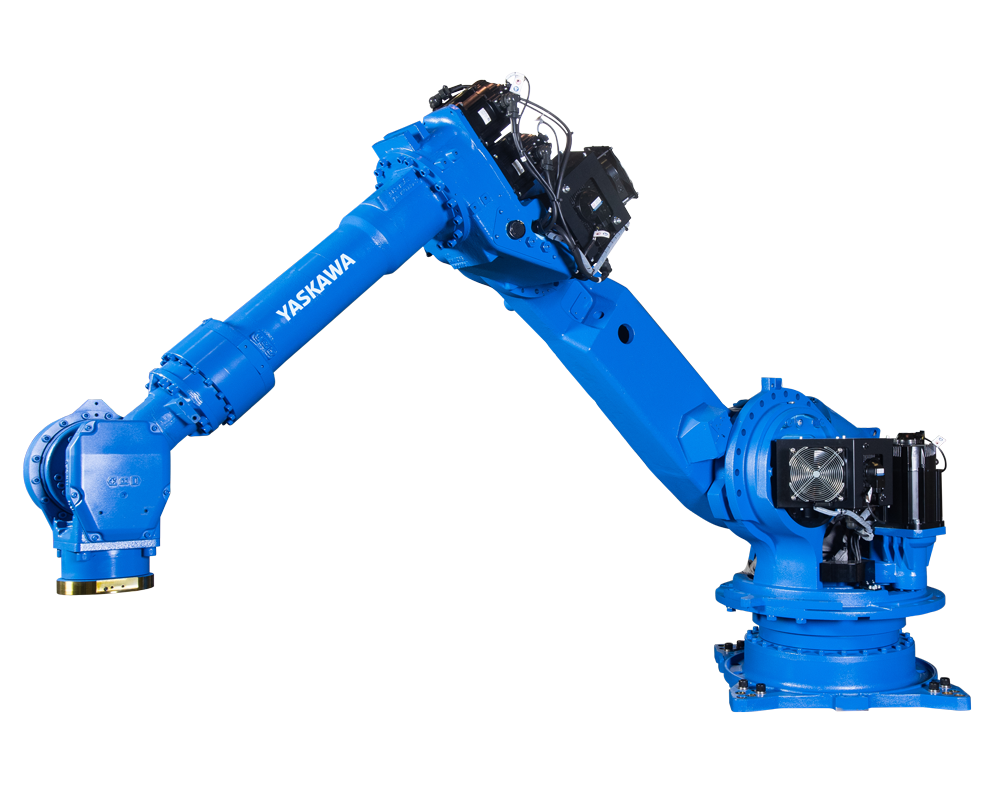

Robot Optimized for Spot Welding

MOTOMAN-SP Series

Yaskawa has raised the bar with its revolutionary "short processing" concept for spot welding with the MOTOMAN-SP robots that are compatible with the new YRC1000 robot controller.

SP100

SP100B

SP210

SP225H

SP225H-135

Multi-Purpose Robot

MOTOMAN-SG,GP,MPP Series

Yaskawa builds optimum facilities with a complete lineup and the new YRC1000 robot controller.

SG400

MotoMINI

GP8

GP25-12

GP225

GP400R

MPP3H

Robot Optimized for Press Handling

MOTOMAN-PH Series

PH130F

PH130RF

PH200RF

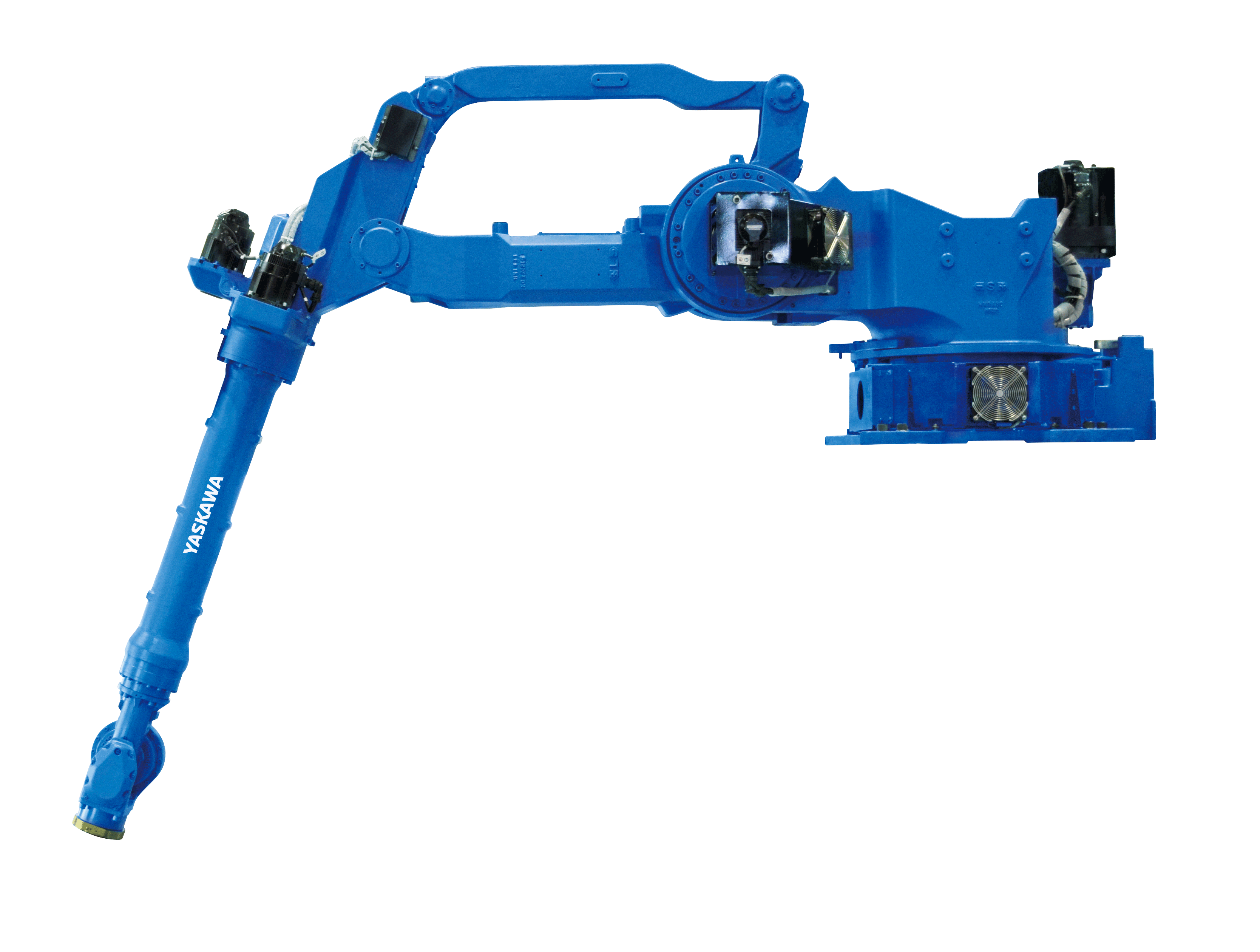

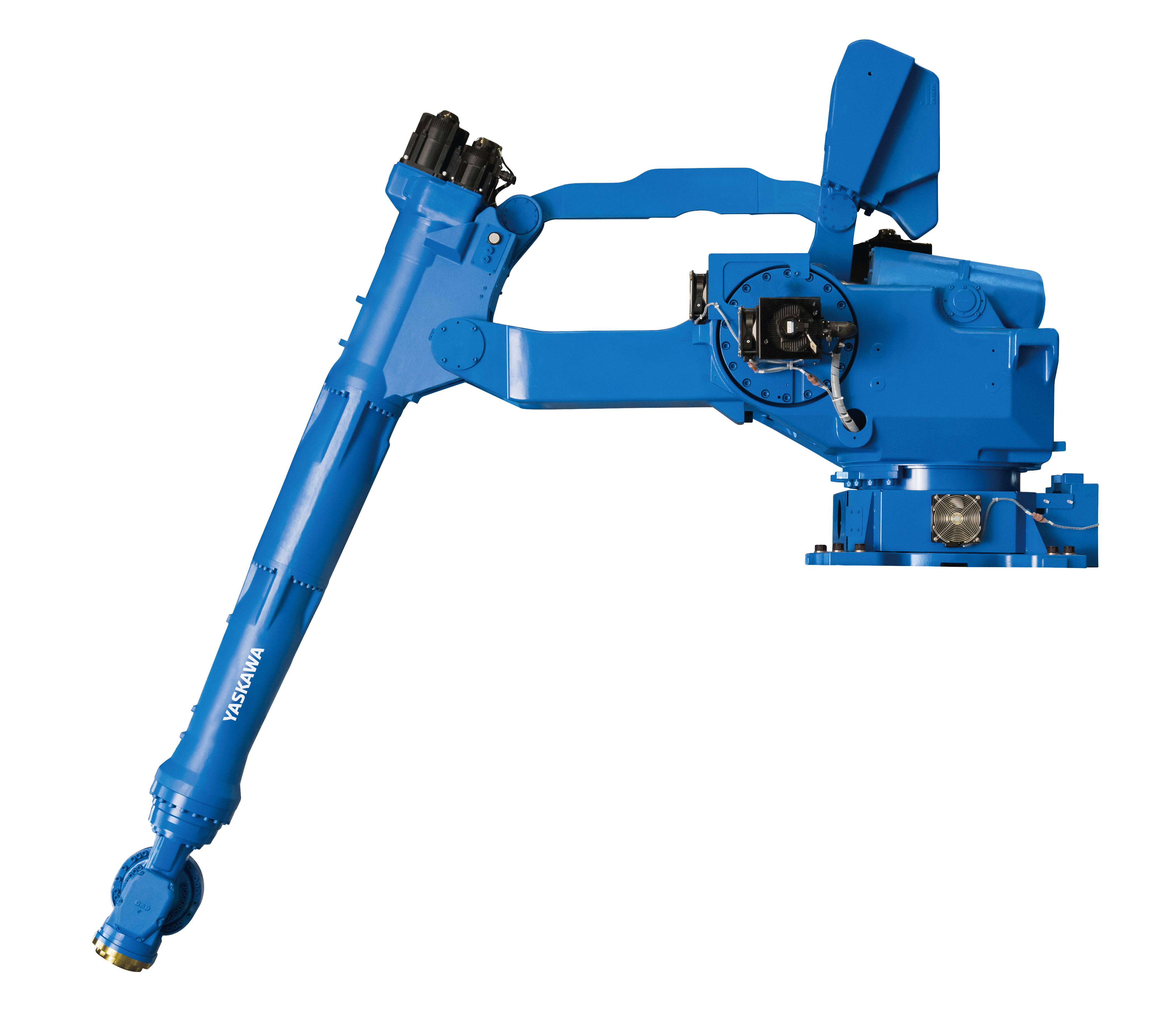

Robot Optimized for Palletizing

MOTOMAN-MPL Series

Complete Lineup to Help Build Optimum Palletizing System

MPL80 II

MPL160 II

MPL300 II

MPL800 II

Robot Optimized for Painting

MOTOMAN-MPX Series

Complete product lineup for better surface finish

MPX1150

MPX2600

MOTO FEEDER V

MHP45L

New Generation Robots MOTOMAN

SDA, HC Series

Dual-arm Robot (SDA Series)

"Slim Body and Slim Arms" for easy installation in same space as human

workers.

The new dual-arm robot is designed to resemble the human figure. The robot

has slim arms that are similar to a human's arms in size with seven joints

in each arm. This human-size robot enables to replace the manual work to the

automate operation without changing existing layout of the facility. The

coordinated operation of seven axes for each arm and one at waist has made

it possible to move efficiently with great dexterity requiring no further

exclusive equipment for robots.

SDA10D

Collaborative Robot HC10

HC 10 can work right next to humans, allowing the layout of production lines and production volume

to be easily adjusted.

The HC10 can be used for diversified small quantity production which has traditionally been

difficult to automate, leading to improvement in customer productivity.

HC10DT

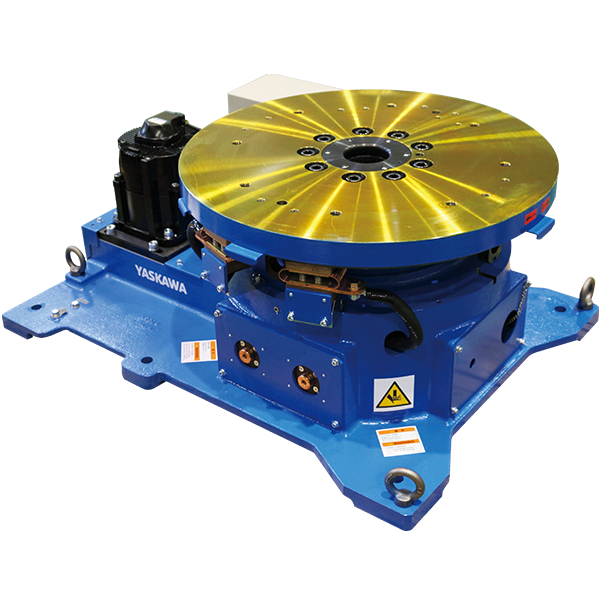

Turntable/Positione

MOTOPOS Series

Keeping Up with the Robot

Do you get irritated with your turntable/positioner, whose speed and accuracy can't

keep up with the robot? YASKAWA has developed turntables/positioners to perfectly

coordinate with the high performance of our robots.

D250F(D500F)

.png)

S500F

T2000F

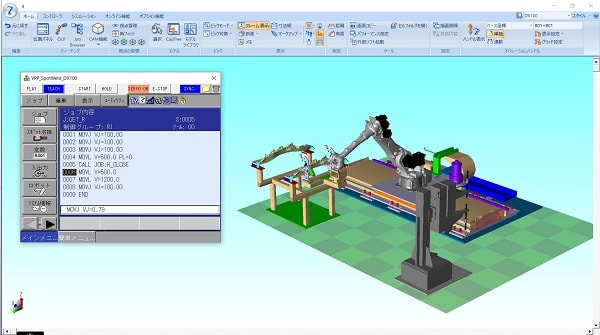

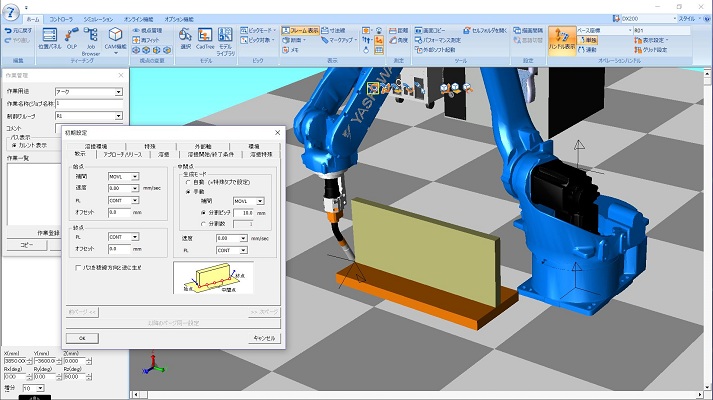

Offline Programming Tool for MOTOMAN

Robots

MotoSim EG - VRC

High-precision offline programming

and testing now easier with the new robot simulator!

MotoSim EG, a high-performance software program, saves you time and simplifies

common engineering task such as interference checks and programming. MotoSim EG

enables you to construct a virtual production facility on a PC with 3D CAD data.

With the latest robot models and functions, faster startup for new lines and shorter

teaching times can be now realized.

MotoSim VRC Spot

Offline Cam

Robot Welding

Long life system solution for all welding requirements

Ever since 1950, we’ve been developing innovative comprehensive solutions for arc welding and resistance spot-welding. Like our Cold Metal Transfer technology CMT. This revolutionary welding process has swept away one old prejudice: that you can’t weld aluminium and steel to one another. Day-in, day-out, we’re working on our vision: to ‘decode the DNA of the arc’. No wonder that we’re the welding-sector’s technological leader worldwide, as well as being the European market leader.

LONG-LIFE SOLUTIONS FROM THE WORLD MARKET LEADER AND INNOVATION

PACESETTER.

Fronius is the strong partner that provides every robot brand, every

system and every application with outstanding technologies and excellent

service. We have a decades-long track record as a system supplier to all

relevant sectors. In this, we insist on always delivering the same high

quality, everywhere, every time. As a single source supplier, we achieve

this not least through our worldwide subsidiaries, our huge store of

experience and our excellent service no matter where.

MIG/MAG TPS/i

SYSTEM SUPPLIER WITH OVER 30 YEARS’ EXPERIENCE.

At Fronius, tradition and experience are close companions. For more than

30 years now, we have been delivering superlative product quality in the

field of robot welding. The close working relationships that we have

with our customers and with all robot manufacturers mean that we are

completely familiar with their industry and their requirements.

MIG/MAG CMT

The systematics of the series

Industrial series production has its own rules: defined quality, defined process

times, defined costs. And in theory, boundless reproducibility. In reality however,

there is a multitude of influencing factors that can increase reject rates or

downtimes and thus impact on the overall profitability of the production

operation.

These include operating faults, variations in the quality of the material or the

effects of thermal deformation during the welding process. If a fault is not

discovered and rectified immediately, the robot will reproduce it all along the

assembly line. The issue here is that the robot must be able to think in order to

evaluate a problem for itself.

In developing the TPS/i, we put the user’s perspective at the heart of all our

deliberations; instead of developing an additional feature for a power source, we

instead wanted to tailor the welding process perfectly to the needs of individuals.

We also took the entire production context into consideration while improving our

robot welding systems.

The result: unsurpassed quality, highest efficiency and maximum

reliability.

In other words, profitable welding processes for all automated series production

lines.

Efficiency

Highest efficiency is possible. Now that TPS/i Robotics is setting new standards

with intelligent performance.

Efficiency is a prerequisite for commercial success. And this is just one area where

TPS/i Robotics is setting new standards. Program setup, welding speed and

maintenance provide the highest levels of competitiveness and profitability in

modern series production.

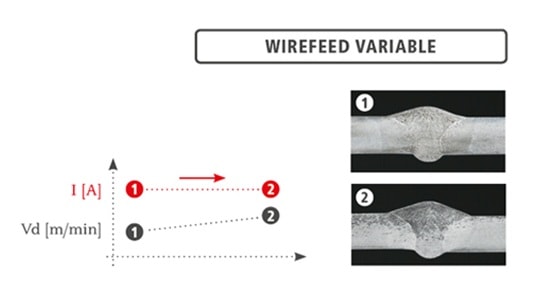

Longer service life for wearing parts

Improved heat management in the wirefeed-distance reduces the thermal load on the

wearing parts. A special contact tip design also reduces the heat absorption through

the arc.

Quality

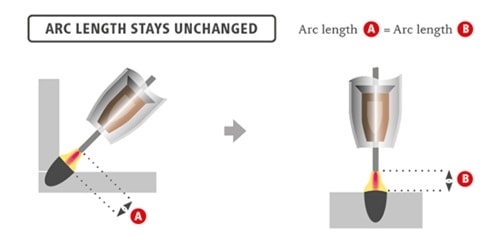

Exceptional welding quality is possible. Because TPS/i Robotics generates the

intelligent arc.

Fronius welding systems have always been the industry standard for the ultimate in

quality. Our mission is to decode the arc, with the goal of producing seemingly

impossible joints between materials. In addition to a range of functions that

improve the arc, TPS/i Robotics ensures complete process documentation.

Privacy Policy

Copyright © 2016 Iwatani Malaysia Sdn.Bhd. All Right Reserved.