Our product design will work closely with customers during the early development stages of a project.Our designer will design the products according to customers’ requirements. We will show both 2D and 3D design drawings so that our customer can fully understand the concepts and details of the product design.We also can arrange for make product with 3D printing.Once customer approved, the designer will begin to design the mould.

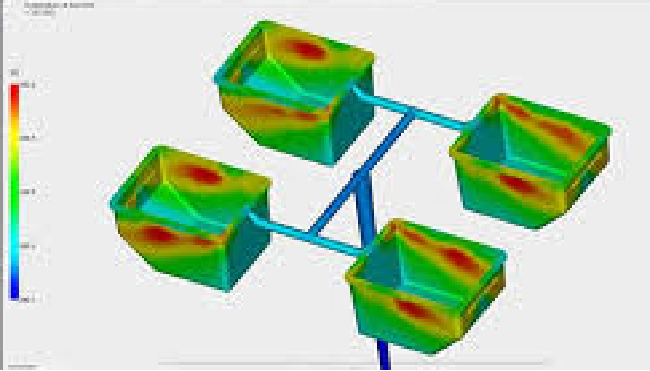

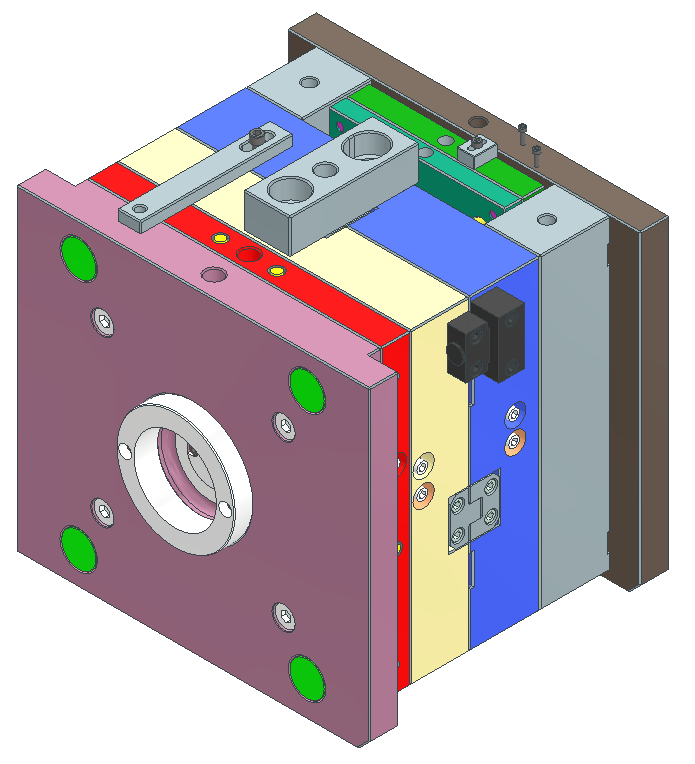

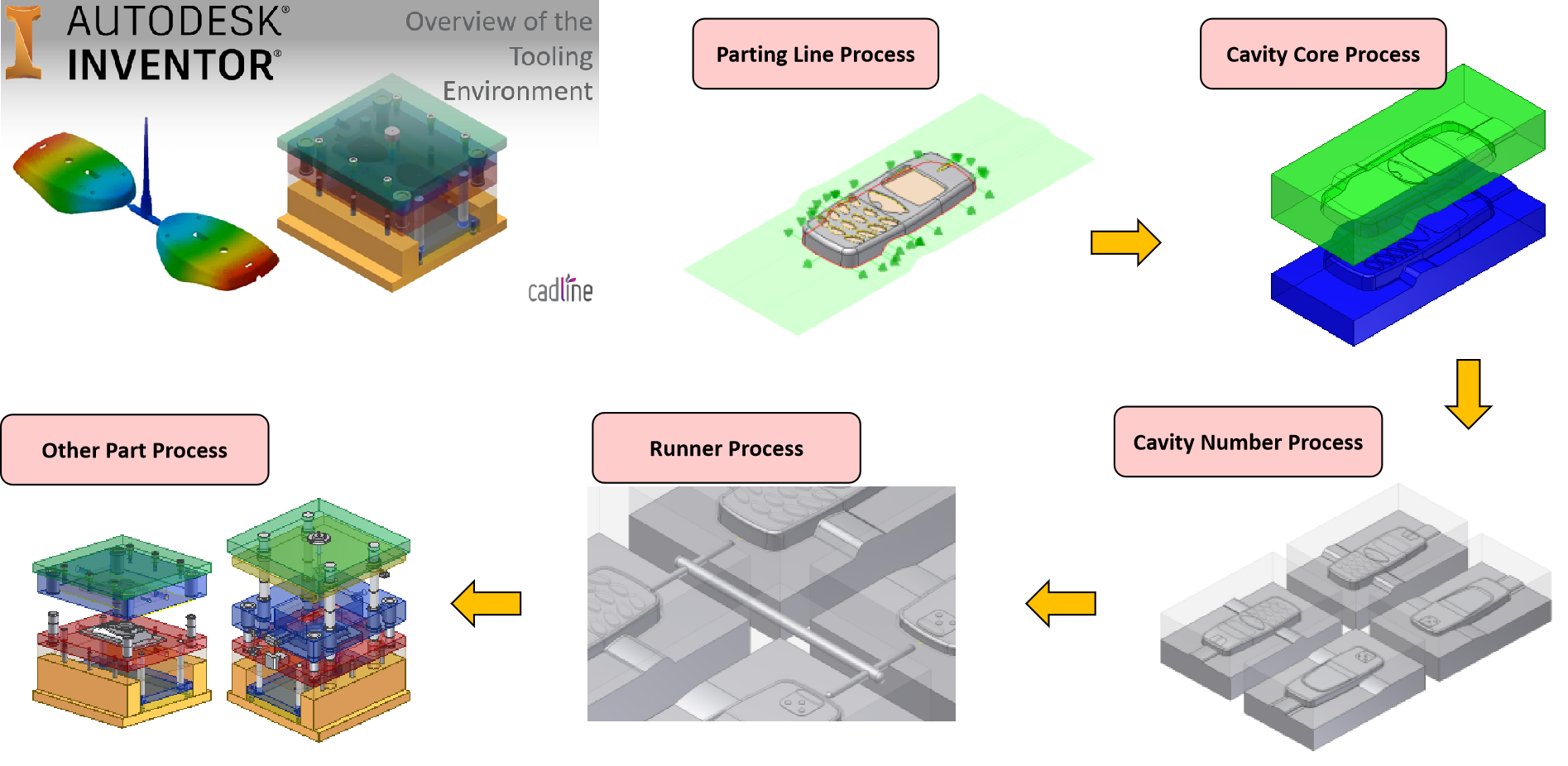

Once the product design is done. Our designers will design the mould according to customers’ requirements. We provides complete fully detailed mold designs with prints of all the mold components(2D data). This includes the mold layout and assembly drawings with a separate bill of material. There is a design check list to assure the mold design is completed and meets high standards for quality. We offer detail 3D mold design services ranging from simple parting line splits to full 3D mold assemblies using 3D software. We believe that we offer the best design and engineering services. We are continuously improving our capabilities to meet our customers’ more and future need. After customer approved the mould design, we will process mould components making.

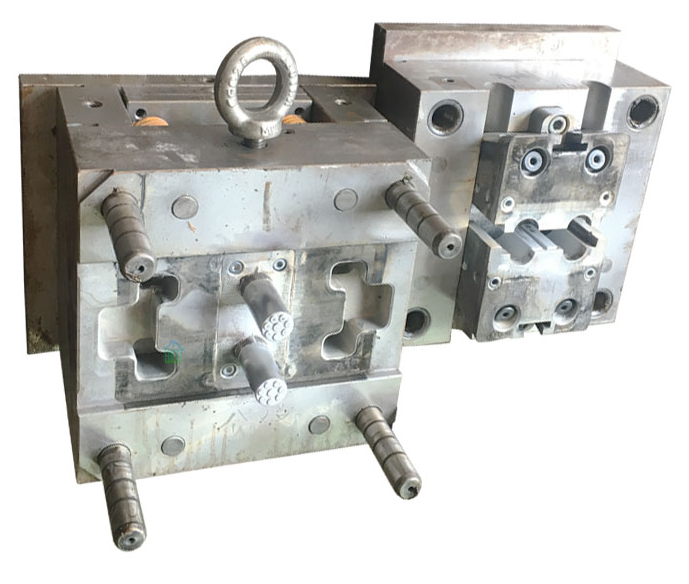

Once the design is done. Our mould maker will create the tool according to the design . The working of the mould is also done by both departments, leveraging high technology and manpower to create closer, much accurate and high quality of mould. We also provide quality control check list and measurement data of insert. We believe that is to best for control mold making. we also assemble whole mold based on assemble drawing from mold design. After mold assemble finish, we will arrange to next step for trial production.

After the mould is completed, we will install the mould in injection machine to test sample (Trial Production) for the customer to check the product.

When product after production, dimension had NG(No Good) point, we will reprocess the insert and retrial production until product dimension all completed.

After customer approved, the product will be officially put into next step of mass production.

After approved the trial production from our customer. We will install the mould in injection machine to mass production. And also plan the manufacturing schedule.

After start manufacturing, we also will process quality control and packaging for delivery to customer place.

After product quality control and packaging, we will control the mass production line for process, and also control the schedule for arrange truck or transportation for delivery to customer place.

Privacy Policy

Copyright © 2016 Iwatani Malaysia Sdn.Bhd. All Right Reserved.