Iwatani provides a wide variety of resin materials and products including PET resin, various raw materials from commodity to engineering plastics, intermediate products such as films, sheets, and non-woven fabrics, and air conditioning panels. Rising an environmental awareness worldwide, Iwatani focuses on environmentally-friendly products such as biomass PET resin, biomass PP/PE/PS resin, bio-based foamed sheets, and highly recyclable aluminum catalyst PET resin which has low environmental impacts.

*Photo is for illustrative purposes only.

*Photo is for illustrative purposes only.

Leading the Industry as First to Offer Bio-PET Resins

In 2010, Iwatani began to develop biomass PET resin. Iwatani offers integrated solutions from PET resin production to processing of final products, taking advantage of the supply system and supply chain we acquired over the years.

A variety of raw materials support every aspect of our daily lives, such as steel, glass, and ceramics. In a country like Japan with few natural resources, a stable supply of high-quality raw materials is vital for industrial activities. We select optimal raw materials from domestic and foreign sources to ensure a stable supply of materials, including mineral sands, raw materials for refractories, rare earth elements, and inorganic chemicals that meet the specific requirements from our customers. We are also actively involved in the development of new materials.

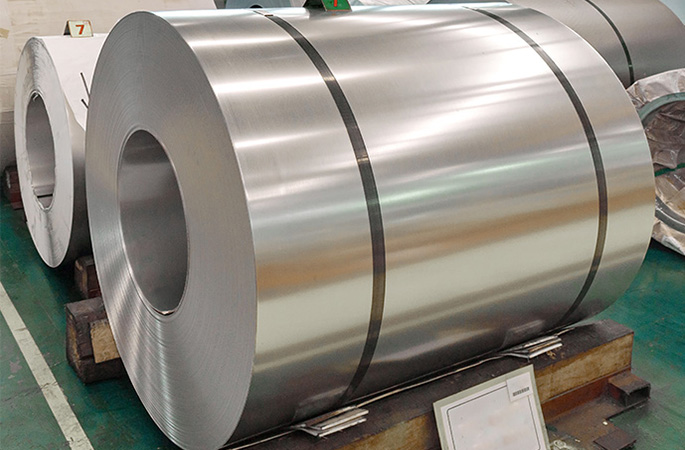

We cover materials and processed products on a global scale, with a special focus on stainless steel, aluminum, and high alloy steels. Via operating companies both in Japan and overseas, we provide materials and products to the growth sector, including the automotive, air conditioning, electronic, medical, and environmental industries. We contribute to society by offering high performance materials and processed products to move the world closer to achieving the SDGs and establishing a decarbonized society.

Drawing on our global network to offer optimal solutions

Iwatani maintains a procurement network and processing sites both in Japan and overseas and has established an optimized supply chain to supply products to meet the diverse requirements of our customers. Selling high performance materials and processed products also helps reduce CO2 emissions at the stage of product use, an important step in achieving the SDGs and establishing a decarbonized society.

Iwatani offers state-of-the-art display devices and technologies, including rechargeable batteries, organic EL displays, and vehicle displays, key elements in achieving a decarbonized society, as well as a wide range of materials used in devices essential to our everyday lives. Examples include the semiconductors and electronic components at the heart of autonomous driving and 5G high-speed communications. Iwatani also supports technological innovation in electronics in terms of basic materials by adding new value to resins, ceramics, and metals. Iwatani takes advantage of its manufacturing and processing capabilities in China, Southeast Asia, and a growing range of regions worldwide.

New Business Development Department specializes in development of and investment in new businesses that lie among Materials Division and have yet to be tapped.Fully utilizing overseas networks, this department primarily sets up biomass fuels and other environmental businesses, investigates overseas investment opportunities and carries out research and development into next-generation materials through cooperation between industrial enterprises and universities.

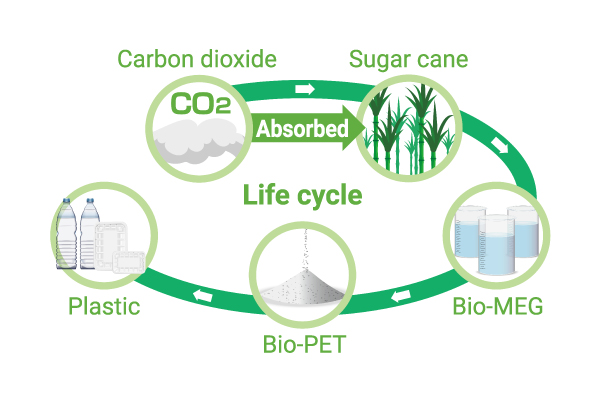

Bio-PET resins are manufactured using 30% of bio-based raw materials of monoethylene glycol refined from molasses, a byproduct of sugar cane processing. Iwatani started selling bio-PET resin in 2010 and currently has No. 1 market share in Japan.*

*Based on Iwatani data as of December 2021 (30 thousand tons handled in 2021)

In order to promote sales of sustainability-conscious raw materials, Iwatani conducts research based on Life Cycle Assessment (LCA), which quantitatively evaluates the impact of raw materials on the ecosystem and the environment from the development stage. In 2011, DNP, Tokyo City University, and Iwatani conducted a joint research and survey on LCA of bio-PET resin. As a result, we found that biomass PET can reduce CO2 emission by 28% (1.7kg per 1 kg of biomass PET) from the production process to consumption, compared to normal PET.

Biomass PET resin is made from biomass MEG refined from , a byproduct of sugar cane processing. This allows approximately 30% of PET resin to be bio-based.

Bio-PET resin has virtually identical physical properties to petrochemical-based PET resin, making it suitable for a wide range of applications through simple replacement of currently used PET resin.

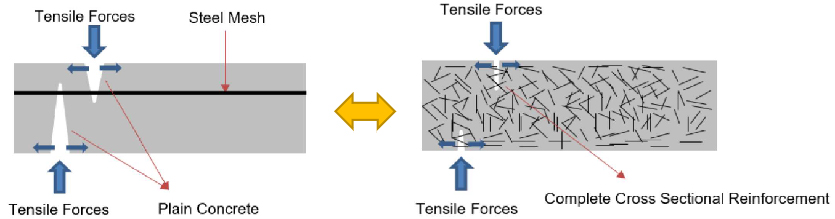

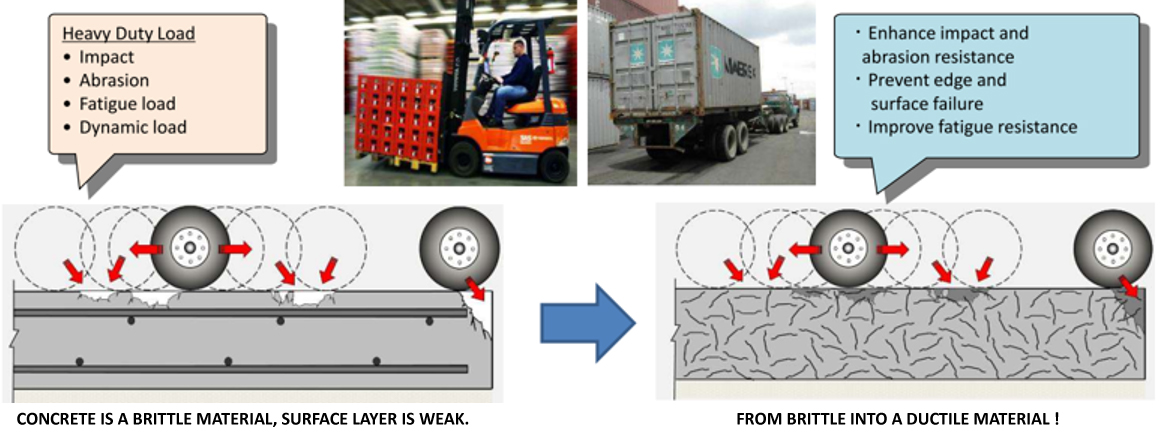

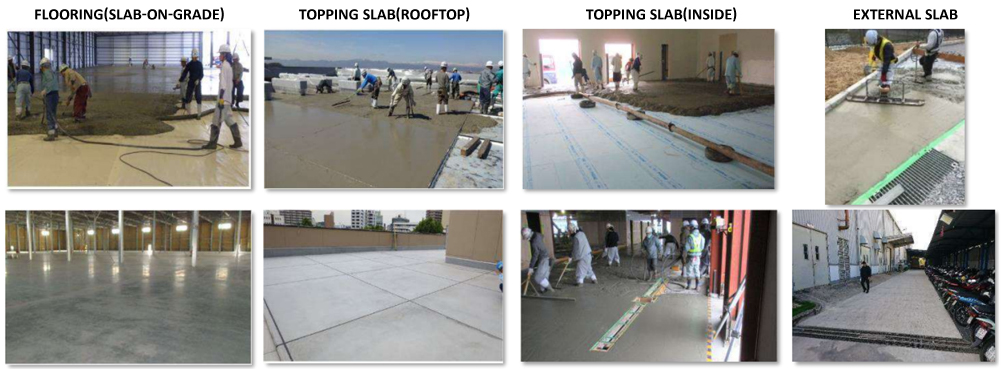

We are working on proposing a new type of concrete reinforcement. This new reinforcing material is a resin fiber, which reduces labor and construction time compared to traditional mesh reinforcement, reduces costs, and solves the problems of traditional mesh reinforcement (Cracks, Rust, Chemical Resistance, Breakage of Mixers and Pumps, etc.).

In particular, unlike iron wire, it is highly evaluated as a reinforcing material that does not rust and is used for waterproof concrete.

When using the product, our professional engineers will support the design, formulation, and usage of each product so that you do not have to worry about it.

Resin Fiber Concrete Reinforcement

1-2 days needed to complete preparation, including compaction, laying plastic sheet, measuring, cutting, carrying and install steel reinforcement or placing wire mesh, prepare steel chairs and spacer blocks, install formwork, level marking, inspection, and correction if needed.

In the past, inferior recycled resins were used just to make them cheaper. However, in recent years, when global warming has become more prominent, countries and companies are promoting the adoption of recycled resins with the aim of reducing greenhouse gas emissions and changing from petroleum-derived resins.

There is a demand for a stable supply of recycled resin that can be replaced with resin. We are committed to supply recycled resin to meet this need.

Recycled Polycarbonate Resin

Iwatani imports PET film widely used for food and industrial applications from a number of overseas manufacturers, mostly in China.

Aluminum vapor-deposited PET film is widely used for food and daily sundries. Iwatani offers products from a number of overseas manufacturers.

Nylon film offers outstanding cold resistance, heat resistance, and gas barrier characteristics, qualities that have led to widespread use for food and industrial applications. Iwatani offers products from overseas manufacturers that meet stringent Japanese quality standards.

This high performance film is designed to help create monomaterial (single material) products that are more easily recycled. Iwatani imports biaxial stretching PE film (BOPE film) from a major global manufacturer that combines excellent printing capabilities, strength, and sealing properties. This material can be used as an alternative to PET/NY to enable all-PE monomaterial products. Iwatani also offers high performance PP/PE/PET films to help achieve monomaterial products.

Detergents, toiletries, hair care products

Shrink labels

Heavy-duty bags

*Photos are for illustrative purposes only.

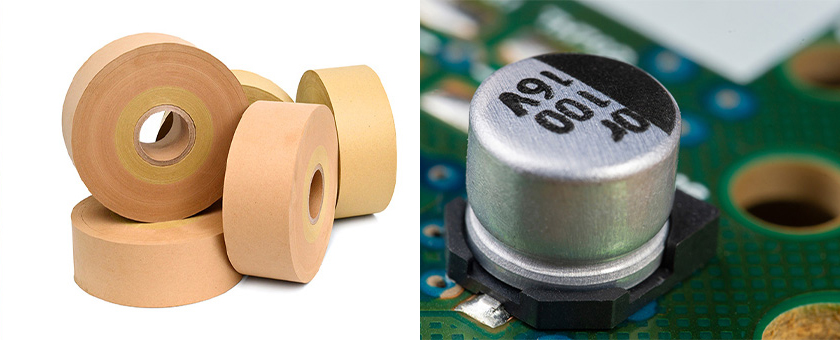

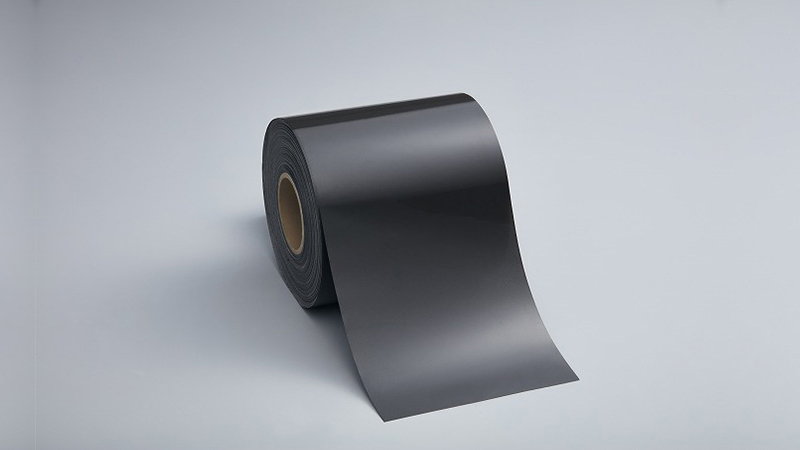

This is dielectric film for use in film capacitors, widely used in applications such as electric vehicles and electronic devices. A simultaneous biaxial drawing system and stringent thickness control enables stable production of thin-film products. Iwatani offers ultrathin products down to a thickness of 2 µm using world-leading manufacturing technology, enabling capacitors to be reduced in size with increased dielectric properties.

| Product Standards | Thickness | 1.9 µm to 14.8 µm |

|---|---|---|

| Main widths | 620 mm, 820 mm, 920 mm |

*Photos are for illustrative purposes only.

These products are separators for compact aluminum electrolytic capacitors with high electrostatic capacity. They’re capable of meeting a broad range of stringent quality requirements, including durability against voltage, storable electrostatic capacity, permeability, and thickness controls.

*Photos are for illustrative purposes only.

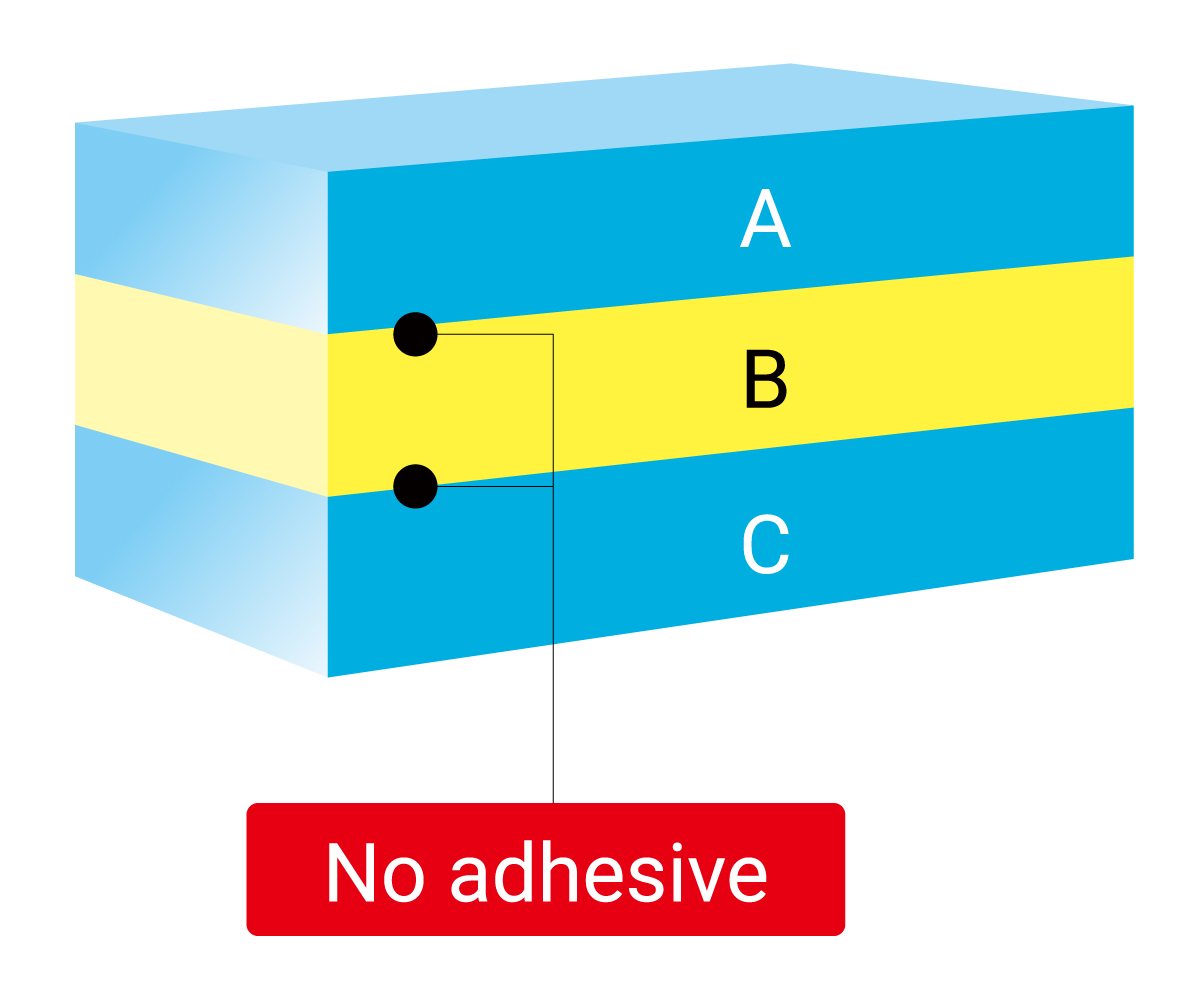

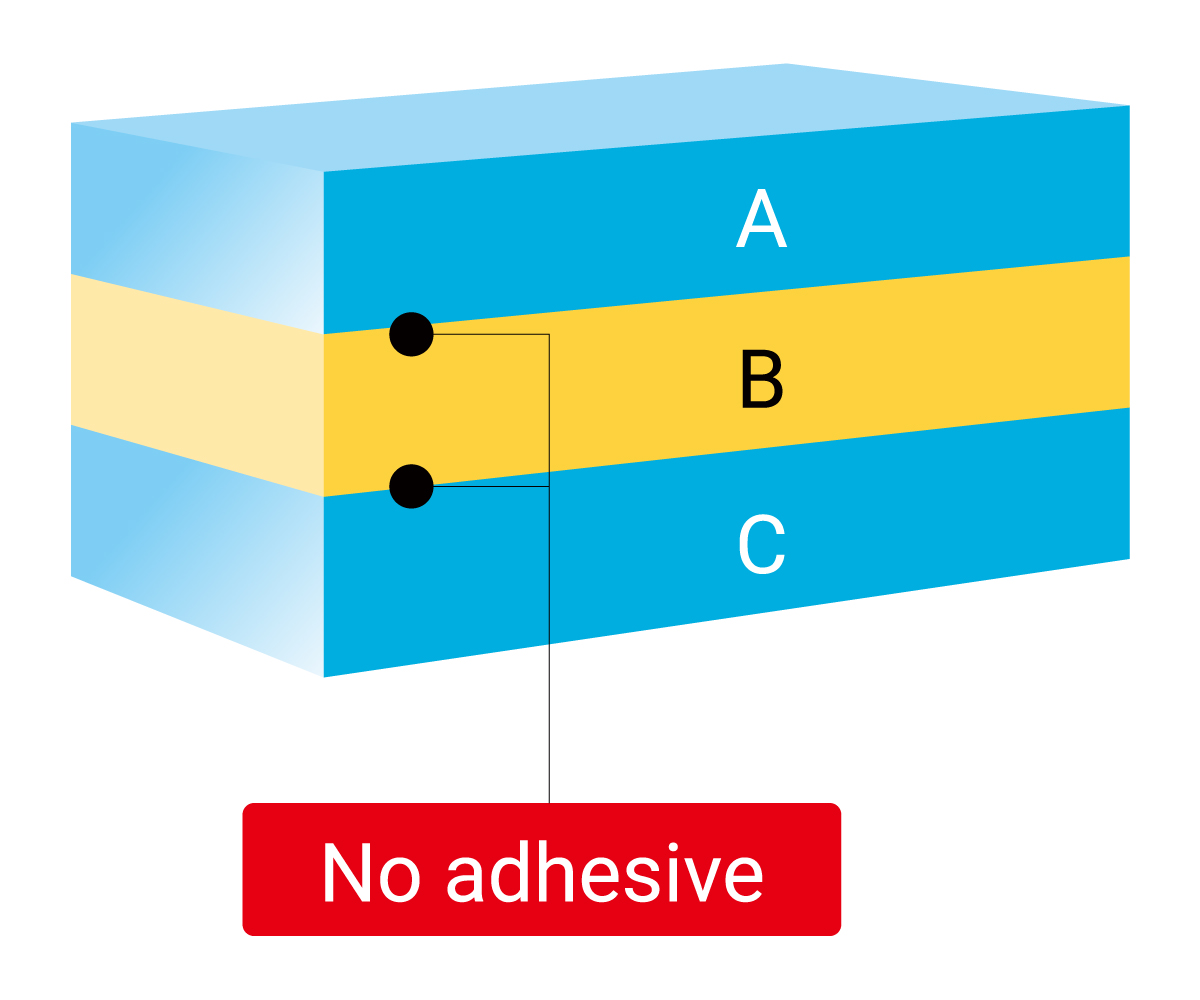

Meta-aramid paper offers excellent surface smoothness and flexibility attributable to calendar processing. It’s widely used as heat-resistant insulation (H type) due to its low halogen characteristics and high heat resistance (UL temperature rating 210°C). Iwatani offers aramid paper manufactured in China.

| Product Characteristics | Applications | Transformer/motor insulation |

|---|---|---|

| Features | Mechanical strength, heat resistance, chemical resistance, etc. | |

| Thickness | 0.04 mm to 0.76 mm |

NSN Heat-Resistant Electrical Insulation Material

| Product | Nominal thickness (mil) | Thickness (µm) | |

|---|---|---|---|

| A | Nomex® (aramid paper) | 2, 3, 5 | 50, 75, 125 |

| B | Torelina® (PPS film) | 1, 2, 3, 5 | 25, 50, 75, 125 |

| C | Nomex® (aramid paper) | 2, 3, 5 | 50, 75, 125 |

NKN Heat-Resistant Electrical Insulation Material

| Product | Nominal thickness (mil) | Thickness (µm) | |

|---|---|---|---|

| A | Nomex® (aramid paper) | 2, 3, 5 | 50, 75, 125 |

| B | Kapton® (polyimide film) | 2, 3, 4, 4.5 | 50, 75, 100, 115 |

| C | Nomex® (aramid paper) | 2, 3, 5 | 50, 75, 125 |

| Product | Flint clay produced in Shandong Province and kaolin produced in Shandong, Shanxi, and Inner Mongolia, China. |

|---|---|

| Applications | Shaped/unshaped refractories, etc. |

| Typical Quality Data | Flint clay, kaolin |

| Inquiries | Minerals Advanced Materials Section Tel: 81-6-7637-3096 |

| Product | Quartz produced in India, Sri Lanka, and China |

|---|---|

| Characteristics | High quality natural quartz (SiO2 purity: 99.6%) is imported directly from the areas of production. |

| Applications | Encapsulant for semiconductors, resin filler, optical glass, raw material for refractories, raw material for casting |

| State | Aggregate, grit |

| Inquiries | (Chubu Area) Tel: 81-52-308-3654 |

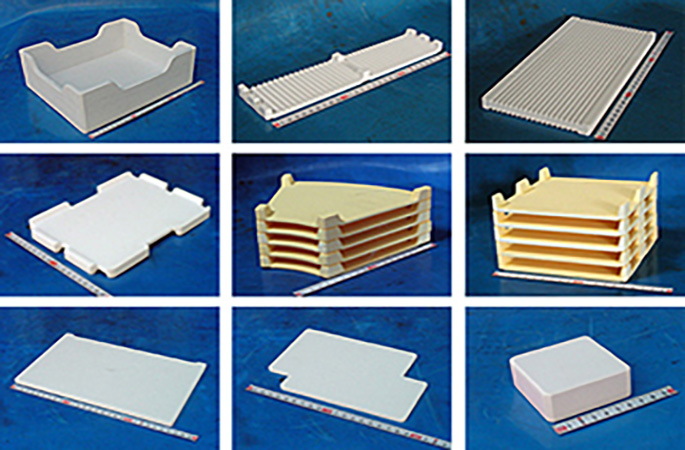

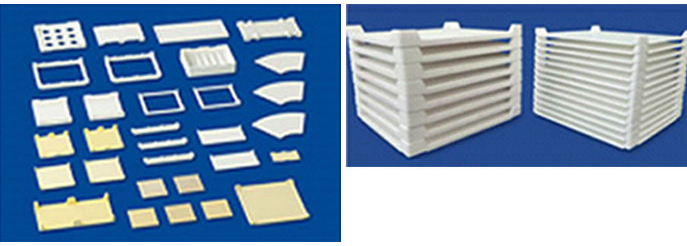

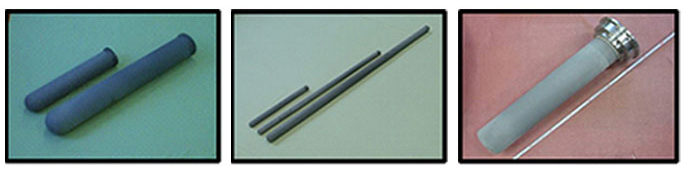

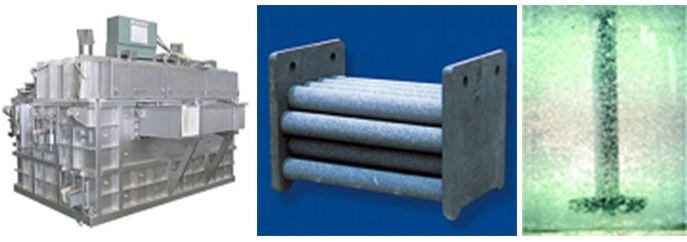

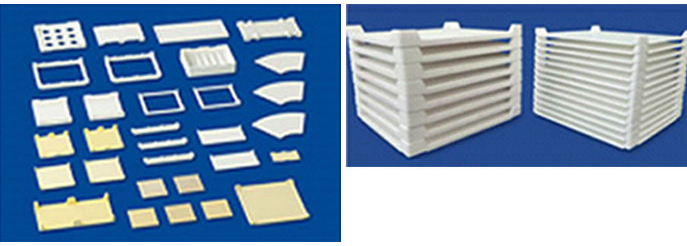

Iwatani is the overseas distributor for products manufactured by the Ceramics Division of Mitsui Mining & Smelting Co., Ltd. This company offers more than 50 years of experience with the kilns and kiln furniture used to fire fine ceramics. Its technologies have won worldwide praise. Iwatani also sells Hi-Cera refractory linings for aluminum castings, as well as the METALOFILTER®, and METALOCLEAN® products, all of which draw on the company’s technological strengths.

| Applications | Kiln tools for sintering furnaces (for electronic components, ceramic components, sanitary ware, ceramicware, etc.) Refractory bricks and lining materials (for high temperature furnaces for firing fine ceramics, atmosphere furnaces, non-ferrous metal melting furnaces, etc.) |

|---|

| Characteristics | Resistant to wetting by molten aluminum; outstanding corrosion resistance and mechanical strength |

|---|---|

| Applications | Used in holding furnaces and low pressure casting furnaces, etc. Heater tubes, thermocouple protection tubes, stalks, rotors, level sensors |

| Applications | Mainly used to eliminate non-metallic inclusions and hydrogen gas from aluminum used to make cans, photocopier drums, magnetic disks, window frames, and automotive components |

|---|---|

| Products Available | METALOFILTER®: Uses the PTF (porous tube filter) method to eliminate non-metallic inclusions from molten aluminum. METALOCLEAN®: Eliminates hydrogen gas from molten aluminum. |

| Product | Precipitated silica (white carbon) produced in India |

|---|---|

| Characteristics | Referred to as white carbon due to its use as an alternative to carbon black, this is typically used as a raw material to reinforce rubber despite containing more than 99% SiO2. |

| Applications | Rubber reinforcing material, oxygen absorbent, inks, etc. |

| Inquiries | Mineral Sands Section Tel: 81-3-5405-5835 |

| Characteristics | Resistant to wetting by molten aluminum; outstanding corrosion resistance and mechanical strength |

|---|---|

| Applications | Used in holding furnaces and low pressure casting furnaces, etc. Heater tubes, thermocouple protection tubes, stalks, rotors, level sensors |

| Applications | Kiln tools for sintering furnaces (for electronic components, ceramic components, sanitary ware, ceramicware, etc.) Refractory bricks and lining materials (for high temperature furnaces for firing fine ceramics, atmosphere furnaces, non-ferrous metal melting furnaces, etc.) |

|---|

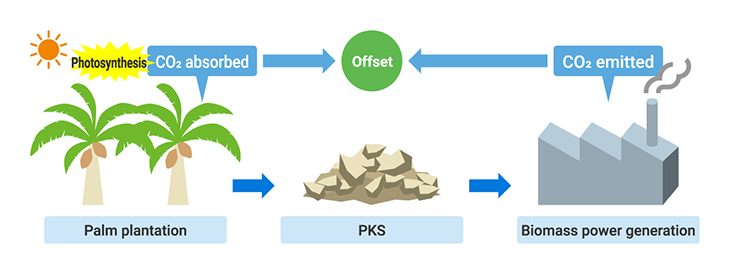

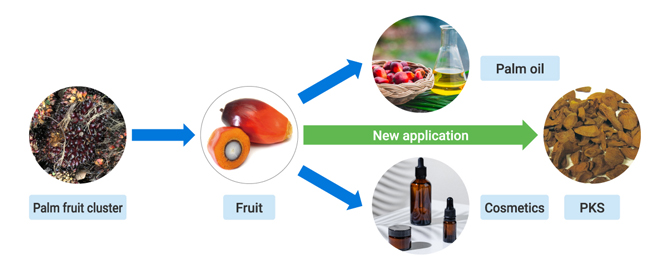

A byproduct produced during the production of palm oil, PKS (palm kernel shells) is used as a fuel in biomass power plants. Iwatani handles PKS produced in Indonesia and Malaysia.

1Stable Long-Term Supply Arrangements

To ensure stable PKS supply, Iwatani maintains long-term relationship with suppliers who operates Crude Palm Oils Mills.

2Flexible Delivery Schedules

Iwatani procures PKS from multiple shipping sites in Indonesia and Malaysia to allow the flexible delivery schedules.

3Strict Quality Control

PKS which moisture and foreign material are controlled will be shipped from Indonesia and Malaysia. Upon importation, we conduct in-house quality analysis at the Iwatani R&D Center, checking constituents, calorific value, specific gravity, and other parameters.

PKS, a carbon-neutral fuel, is derived from the fruit kernel of palm trees, which absorb CO2 when they grow. This offsets the CO2 emitted during combustion, resulting in a net zero impact on atmospheric CO2 levels.

Malaysia and Indonesia grow enormous palm trees, and the harvested palm fruits are mainly used for palm oil and cosmetics production. Conventionally, the remnants of these processes were simply disposed, However those are used as biomass fuel in our own day.

Iwatani has achieved GGL (Green Gold Label) certification. Iwatani’s declaration

Iwatani also handles a wide range of products such as silica sand for use in power generation boilers to assist in the combustion of biomass fuels.

Wood pellet is a biomass fuel produced from thinned lumbers generated at forest and from wood wastes generated at sawmills. Iwatani handles FSC (Forest Stewardship Council) and PEFC certified wood pellets produced primarily in Southeast Asia including Vietnam. Iwatani implements a voluntary code of conduct based on guidelines established by the Japanese Forestry Agency (guideline of certifying woody biomass for electric use).

Voluntary Code of Conduct

As a carbon neutral fuel, wood pellets do not affect emissions of CO2 into the atmosphere. Wood pellets are derived from thinned lumbers, wood wastes and sawdust generated from sawmills, however the originating trees absorb CO2 during their growth cycle, offsetting the CO2 emitted when they are burned. Overall, they have a zero effect on atmospheric CO2 levels. Iwatani works with multiple leading suppliers who operate stable production and quality control systems and offer enough supply capabilities to ensure a stable long-term supply of high quality wood pellets.

Iwatani offers FSC and PEFC certified wood pellets. We are also a certified supplier of woody biomass used for power generation, a requirement for supplying to biomass power plants in Japan.

Iwatani also handles a broad range of other products, including the silica sand feeded to power generation boilers to assist combustion of biomass fuel. Iwatani is working on the commercial development of torrefied wood pellets*, a promising alternative to coal.

*Torrefied Wood Pellet: Biomass fuel with increased calorific value produced by processing wood pellets and other biomass fuels

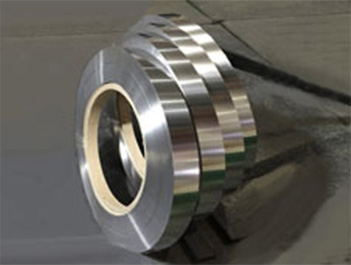

Stainless steel is used across a wide range of sectors, including the automotive industry, communications equipment, and household appliances, and is essential in various state-of-the-art fields. Iwatani supplies stainless steel for applications in a broad range of sectors through its domestic and overseas network and processing sites, and aims to be Japan’s No.1 trading company in stainless steel handling volume.

Coil, sheet, foil, pipe, round bar, section, wire

| Products Available | Characteristics |

|---|---|

| Stainless steel for springs | Features the strong work-hardening properties of austenitic stainless steel. Typical grades are 301, 304, and 631, which can be finished to suit the specified hardness. |

| Ultrathin stainless steel | We offer a wide range of ultrathin stainless steel types, including 301, 304, 430, and 631, manufactured as ultrathin foil, down to thicknesses of 8 µm. |

| Stainless steel for etching | The steel undergoes tension annealing to improve flatness, making it ideal for etching. |

| Surface treated stainless steel | The steel undergoes electropolishing and chemical polishing for improved designability and performance. |

| Non-magnetic stainless steel | Retains its non-magnetism even after extreme cold-working. |

| Stainless steel for gaskets | Features a finer crystalline structure to maintain high spring performance and fatigue characteristics. |

| High-strength stainless steel | We offer stainless steel that’s been cold-worked to a hardness of HV530 or more and precipitation-hardened stainless steel heat treated after forming for increased hardness. |

| Stainless steel for automotive molding | This ferritic steel offers superior mirror finish characteristics compared to BA, and corrosion resistance equivalent to 304 steel. |

| General purpose stainless steel (sheet/bar) | We offer various grades, including 304, 316, and 316L. As a primary trading company, we can procure materials from various companies in Japan, as well as offer lower cost solutions in the form of products sourced from overseas suppliers. |

| Hydrogen-resistant stainless steel | Maintains durability even at extremely low temperatures and high pressures. |

| Duplex stainless steel | Combining the characteristics of both austenitic and ferritic steel makes it possible to reduce thickness—and thereby reduce costs—while continuing to offer excellent corrosion resistance. |

Stainless steel plate processing (cutting and bending)

Stainless steel coil center (leveling processing)

Stainless steel processing (thin plate, plate, bar)

Suzhou Iwatani Metal Products Co., Ltd. and Zhongshan Iwatani Co., Ltd. are Iwatani group companies responsible for precision slitting of precision stainless steel and non-ferrous metal materials. They make possible a wide range of lighter and thinner metal materials for electronics sector applications that demand more compact dimensions, lower weight, resource savings, energy savings, and increased capacity. These companies supply materials for a wide range of domestic applications within China, including rechargeable batteries, liquid crystal, organic EL, smartphones, connectors, and office equipment.

Aluminum is used in a wide range of applications, from chassis for tablets and PCs to bodies and frames for vehicles, bullet trains, and aircraft. Iwatani operates networks and processing sites both in Japan and overseas to supply to a variety of sectors.

Bar, sheet, foil, disks, plate, round bar, pipes, checker plate, braising sheet, colored aluminum, wire, fins

Manufacturers in Japan, the Republic of Korea, China, Hong Kong, Russia, Thailand, Vietnam, Indonesia, Greece, etc.

Iwatani offers optimal materials, including materials sourced from overseas, to meet demands for diversified suppliers and reduced material costs.

| Item | Range of Available Products |

|---|---|

| Alloys | 1050/1060/1070/1080/1090/1100/1235 2011/2014/2017/2024 3003/3004/3005/3006/3104/3105 4004/4045/4104/4343 5N01/5005/5006/5052/5083/5151/5182/5505/5657/5754 6061/6063/6N01/6101 7N01/7075 8011/8021/8079 |

| Thickness | 0.05 mm to 200 mm |

| Width | Up to 2,500 mm |

| Length | Up to 6,000 mm |

| Lead time | From in-stock items ready for immediate dispatch to tailor-made production |

| Standards | JIS/ASTM/ASME/TS 16949, etc. |

| Surface treatment | Anodizing/fluoride coating/zirconium treatment/chromate treatment |

| Material | Features |

|---|---|

| High strength, high heat dissipation | Combines thermal conductivity equivalent to pure aluminum and strength exceeding 5052 |

| High strength, moldability | Combines high strength with moldability, with limit drawing ratios approaching steel plate |

| Electrical conductivity, high strength | Maintains high electrical conductivity and strength |

| Materials with good anodizing properties for decorative automotive applications | Materials with increased anodizing properties as well as brighter sheen following chemical polishing. Products equivalent to 5505/5657 alloys |

| High heat resistant materials | Materials maintaining their strength even under high temperatures |

| Highly reflective materials | High reflectivity imparted through rolling and coating |

| High-adhesion materials | Materials with increased adhesion to resins, paints, and other non-metallic materials |

| Surface treated materials | Materials subjected to functional surface treatment, including heat dissipation, heat resistance, strength, corrosion resistance, scratch resistance, and electrical insulation |

| Materials recommended for anodizing | Materials manufactured overseas and suitable for anodizing |

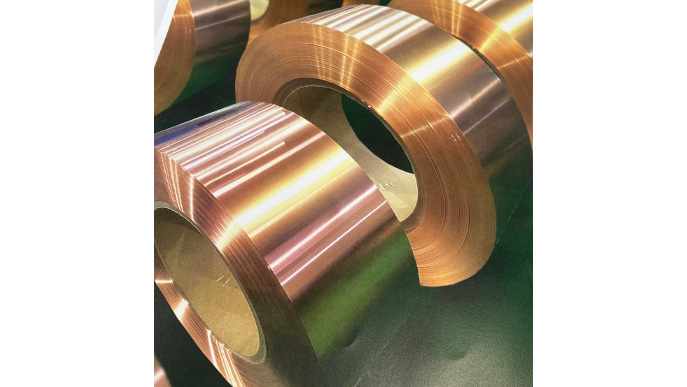

Copper materials are used in a wide range of consumer and industrial applications, particularly those related to vehicles, electronic components, air conditioning, and water heaters. Iwatani offers products to meet specific customer needs, including oxygen-free copper, tough pitch copper, and phosphorous-deoxidized copper.

Copper pipe, copper bar* Supplied in coil or sheet form.

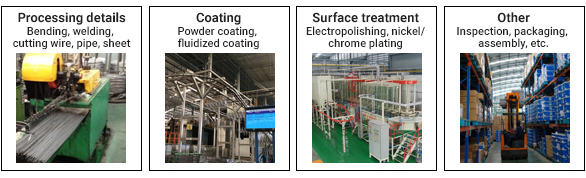

Operating its own wire processing plants in Japan, Thailand, and China, Iwatani has established a production system that spans all stages, ranging from materials to processing. Iwatani currently holds the leading market share for fan guards incorporated into Japanese air conditioning units manufactured in Japan, Thailand, and China. To ensure eco-friendly manufacturing, plants in Thailand and China feature solar power systems.

To meet customer requirements, all stages of processing up to the final product are handled at Iwatani Group companies and plants, both in Japan and overseas. The ability to handle all processes in-house—from the bending and welding of steel and stainless steel wire to resin coating by painting or fluidized coating—helps minimize manufacturing costs.

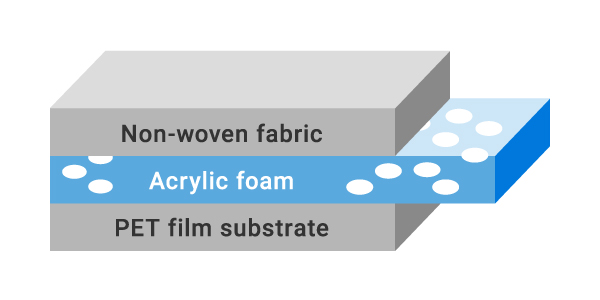

Offers industry-leading impact absorption and reliable performance even in high- or low-temperature environments. Helps protect electronic devices for cutting-edge applications involving smartphones and vehicle-mounted devices.

Vehicle-mounted devices, industrial devices, and medical devices requiring high reliability, durability, and weather resistance

Other materials

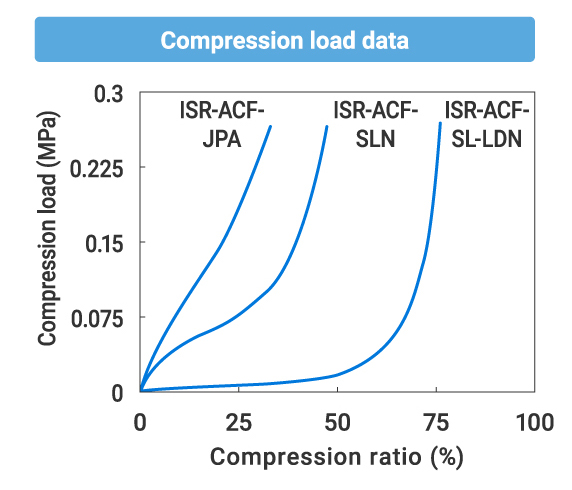

High-impact absorbent acrylic foam

High-impact absorbent acrylic foam

1Basic Physical Properties

| Grade | Item | ISR-ACF-JPA | ISR-ACF-SLN | ISR-ACF-SL-LDN |

|---|---|---|---|---|

| Thickness | mm | 0.06 to 0.25 | 0.1 to 1.0 | 0.1 to 2.0 |

| 25% compression load | MPa | 0.18 | 0.08 | 0.01 |

| Density | g/cm3 | 0.7 | 0.5 | 0.3 |

2Compression Load Test

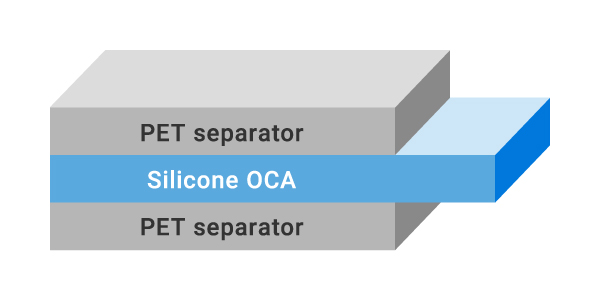

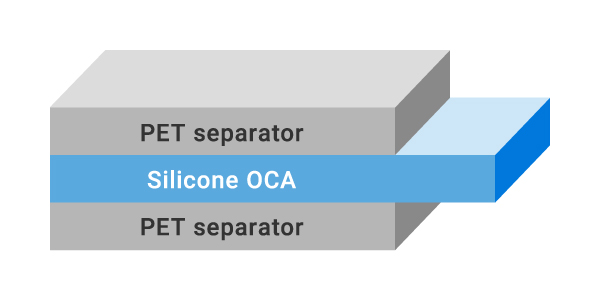

This silicone type OCA offers long term reliability and optical stability, with minimal yellowing even under UV light or in high temperature environments. It also offers outstanding haptic characteristics in displays incorporating haptic technologies (tactile sensor technologies), an area marked by advances in recent years.

1Basic Physical Properties

| Product Grade | TK 50 | TK 100 | TK 200 | |||

|---|---|---|---|---|---|---|

| Thickness | 50 µm | 100 µm | 200 µm | |||

| Optical characteristics | Haze | Glass/OCA/glass | % | 0.3 | 0.4 | 0.8 |

| Total light transmittance | 350 nm to 800 nm light transmittance | Glass/OCA/glass | % | 93 | 93 | 93 |

| Adhesive force | Optical glass | JIS Z 0237 | N/25 mm | 20.5 | 20.5 | 27.5 |

| 180° PEEL | ||||||

| Step conformance | Step height | Immediately after roll lamination | µm | 0 | 0 | 0 |

| After autoclaving | µm | 10 | 35 | 50 | ||

| 50℃ *0.5 MPa *30 min | ||||||

2Light Resistance Test

3Weather Resistance Test

This silicone OCA is intended for use in rollable displays able to withstand over 600,000 bending cycles. The soft silicone OCA offers outstanding impact absorption properties, making it ideal for use in bonding next generation display components.

Foldable and rollable devices requiring high bending performance

1Bending Test Data

| Cycles | 1,000 | 10,000 | 80,000 | 200,000 | 600,000 |

|---|---|---|---|---|---|

| Test data for 20 µm to 50 µm thickness | Clear |

Clear |

Clear |

Clear |

Clear |

2SS Curve Data

3Impact Absorption Characteristics

Iwatani handles raw materials and supplementaly materials used in semiconductors and HDDs that meet strict quality demands. We offer materials sourced not just from Japanese manufacturers, but from our overseas network.

| Product | Typical purity |

|---|---|

| Magnesium (Mg) | 99.99% (4N) |

| Aluminum (Al) | 99.999% (5N) |

| Silicon (Si) | 99.9999999% (9N) |

| Calcium (Ca) | 99.9% (3N) |

| Scandium (Sc) | 99.99% (4N) |

| Iron powder (Fe) | 99% (2N) |

| Cobalt (Co) | 99.95% (3N5) |

| Zirconium (Zr) | 99.95% (3N5) |

| Niobium (Nb) | 99.9% (3N) |

| Tin (Sn) | 99.999% (5N) |

| Hafnium (Hf) | 99.95% (3N5) |

| Tantalum (Ta) | 99.9% (3N) |

Iwatani handles high purity inorganic materials sourced from both Japanese and overseas manufacturers. These products are used as raw materials for the sputtering targets essential in forming functional thin films, including semiconductors, HDDs, and magnetic devices. In addition to the raw materials listed below, Iwatani offers high purity metals, Rare Earth metals, and a range of inorganic compounds, including nitrides and borides that show promise as next generation recording media.

Iwatani offers packaging materials that meet high cleanliness standards including moisture vapor barriers required for semiconductors and HDDs. These products are processed in Class 1000 cleanrooms. We can also provide an analysis of particle and ion contamination.

| Product | Main features |

|---|---|

| Aluminum foil type | Provides complete moisture vapor barriers within the package. |

| Transparent type |

Allows inspection of package contents while maintaining robust barrier functions.

|

We were just looking for potential business partners to expand our operation. We can help you find potential clients for your product.

We have a global group network centered on Asia, America, Europe, etc. As your business partner, it is possible to develop your company's unique products and unique technologies using our network. Please contact us if you would like to develop a new sales scheme.

Please fill in the necessary information from the contact form and send it. Our representative will confirm the content you have sent.

If we would like to confirm the details, we will contact you for the meeting.

We will explain the details about the start of trading.

We are looking for Malaysia's own original brand products.

We are looking for Malaysian household goods and home appliances. Please contact us if you are a company that manufactures original home appliances, home appliances, or your own brand. We can use our network to help you expand outside of Malaysia.

We are looking for Malaysian Palm Kernel Shell supplier.

We are looking for Malaysian Palm Kernel Shell supplier. Please contact us if you are a company that manufactures Palm Kernel Shell. We can use our network to help you expand outside of Malaysia.

Privacy Policy

Copyright © 2016 Iwatani Malaysia Sdn.Bhd. All Right Reserved.